As industries continue to evolve and demand higher efficiency, the role of automated warehouse systems has become increasingly critical. PassionIOT, known for its advanced warehouse automation solutions, plays an essential role in helping companies modernize their material handling processes. These systems significantly improve productivity by integrating cutting-edge technology into warehouse operations.

What Is an Automated Warehouse System

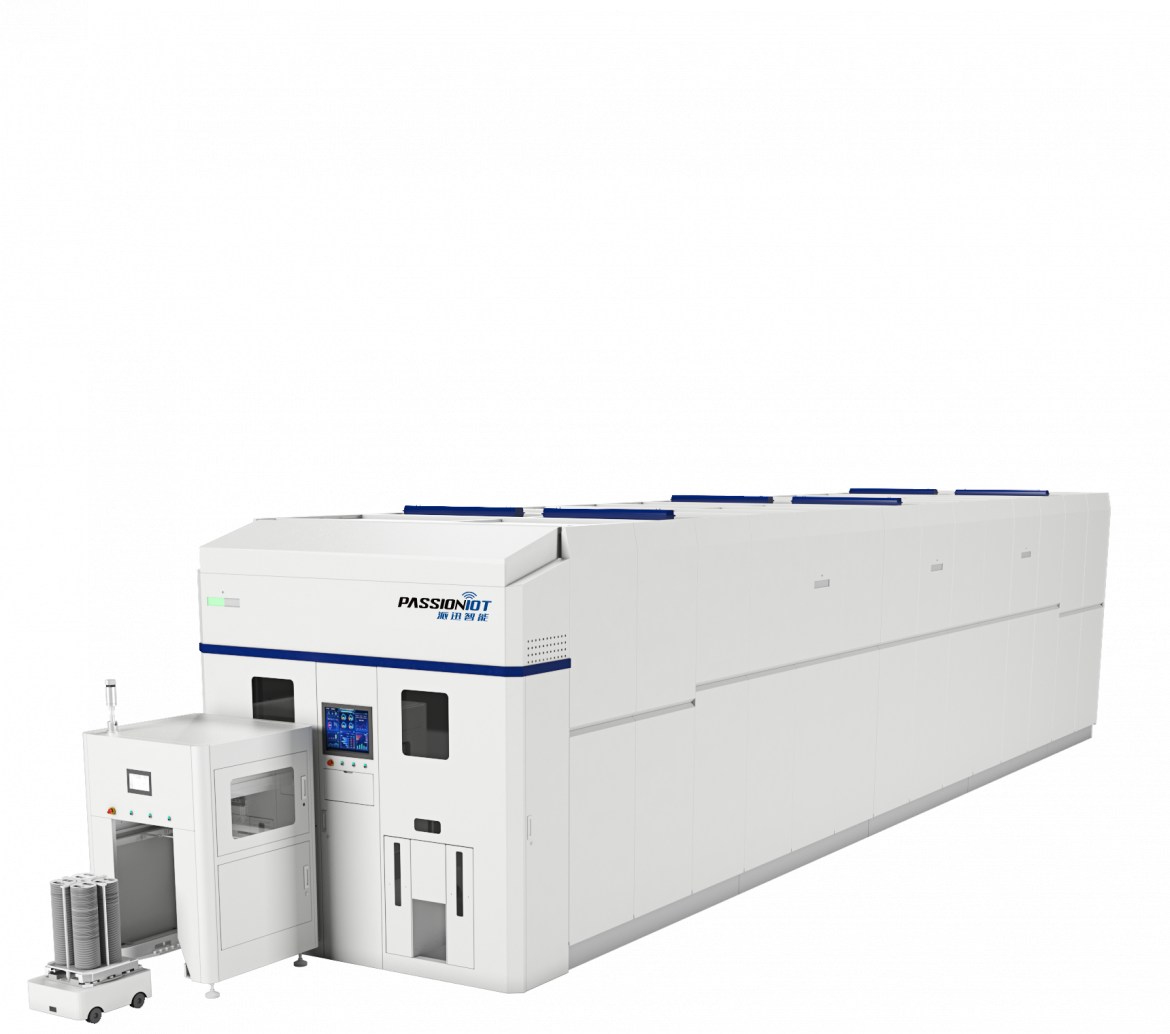

An automated warehouse system is designed to streamline the process of storing, retrieving, and distributing goods in a warehouse setting. These systems are often powered by advanced technologies like robotics, conveyor belts, and automated guided vehicles (AGVs). A key component of warehouse automation solutions includes vertical storage systems—used to maximize storage space by utilizing vertical height.

Vertical storage system manufacturers like PassionIOT are instrumental in designing solutions that cater to the specific storage needs of different industries. Their expertise allows for more efficient use of available space, reducing the need for manual intervention and ensuring that inventory is always organized and accessible.

Key Components of Warehouse Automation Solutions

Warehouse automation involves several technologies working together to improve operational efficiency. Key components of warehouse automation solutions include SMD storage systems and vertical storage systems. SMD storage systems provide highly organized spaces for components like surface-mounted devices, which are essential in electronics manufacturing.

These systems, provided by vertical storage system manufacturers such as PassionIOT, help businesses save time and reduce errors in material handling. Through these technologies, PassionIOT enables companies to achieve faster processing times and a higher level of operational accuracy in their warehouse operations.

The Future of Automated Warehouses

Looking ahead, the future of automated warehouses is filled with promise. As the demand for speed and efficiency continues to rise, warehouse automation solutions are evolving to include smarter, more flexible systems. Innovations such as machine learning and artificial intelligence will allow warehouses to predict stock levels, optimize storage, and manage operations more effectively.

Choosing the right vertical storage system manufacturers like PassionIOT is crucial for businesses looking to stay competitive. With PassionIOT’s comprehensive approach to automation, companies can anticipate future challenges in warehouse management and be prepared for industry advancements.

Conclusion

Automated warehouse systems are a vital part of modern manufacturing. With warehouse automation solutions provided by experts like PassionIOT, companies can significantly enhance their operational efficiency and stay ahead in a competitive marketplace. Whether through vertical storage systems or SMD storage systems, PassionIOT continues to deliver innovative solutions that simplify and optimize warehouse management for industries worldwide.